Completion Effects

Use the Completion Properties panel to enter properties for the well’s completion type. For details on each completion, see:

No Completion — Completion effects are not calculated. Use for openhole completions or when tests measure rates and pressures downstream of the completion.

Screening recommendation

For screening work, select No Completion. Entering unknown completion parameters wastes time and adds no value. When you have a specific goal to model perforations or gravel packs, add those details later.

- Perforated Cased Hole - Quadratic Flow — Pressure drop across open perforations is calculated with the radial quadratic flow equation based on perforation geometry and compacted-zone permeability.

- Cased Gravel Pack Completion — Pressure drop across a perforated cased-hole gravel pack is calculated using the quadratic linear-flow equation.

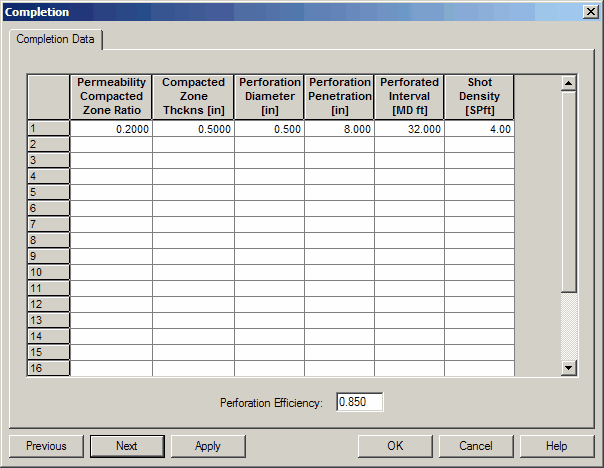

1. Perforated Cased Hole Data

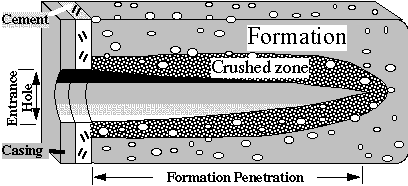

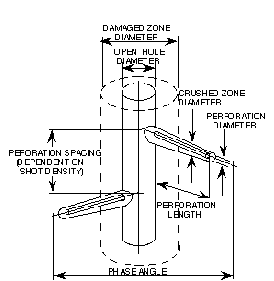

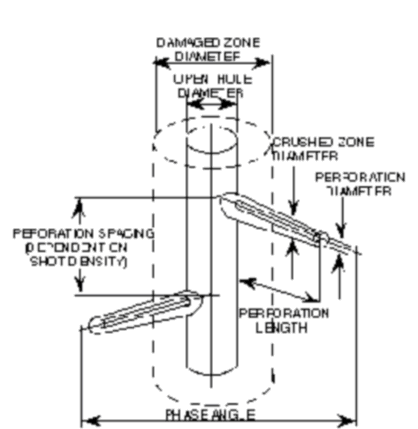

Compacted Zone Permeability Ratio: Perforating with shaped charges creates a damaged zone of reduced permeability around each perforation. The resulting permeability is typically 10–50 percent of the original, depending on overbalanced vs. underbalanced perforating. A recommended ratio of compacted-zone to original permeability is 0.2.

Compacted Zone Thickness (in): Thickness of the reduced-permeability ring around each perforation caused by the perforating process. A value of 0.5 in is recommended.

Perforation Diameter (in): Average hole diameter through casing, cement, and formation. It depends on the charge, gun, and formation strength. API RP-43 certification data for the specific charge provide an upper bound.

Perforation Penetration (in): Average penetration into the formation, excluding pipe and cement thickness. Subtract cement and pipe thickness from published penetration values. The model assumes radial flow from a porous medium into the perforation, so do not include cement or pipe thickness.

Perforated Interval (ft): Length of the perforated section in the zone of interest. Taken from the completion report and independent of formation thickness. In fully perforated deviated wells, the interval can exceed the zone thickness.

Shot Density (spf): Designed or specified number of perforations per foot. The program reduces this number by the entered perforation efficiency.

Perforation Efficiency: Probability that a perforation is effective, equal to the probability of a good fire times the probability that the perforation traverses casing, cement, and the damaged zone. Typical values range from 0.5 to 0.9.

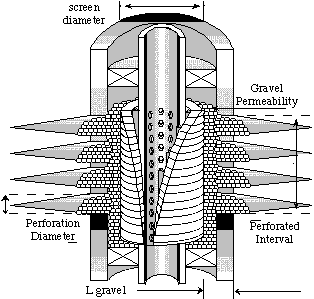

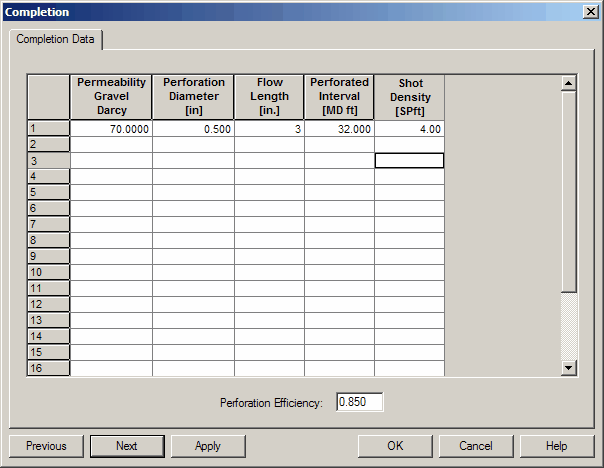

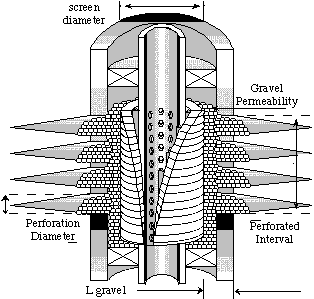

2. Gravel Pack Completion Data

Scope

This method models cased gravel packs. Do not use it for open-hole gravel packs.

GRAVEL PERMEABILITY (Darcys): Depends on gravel mesh size. Typical values:

| Gravel mesh size | Permeability (Darcys) |

|---|---|

| 8-12 | 1000 |

| 10-20 | 400 |

| 20-40 | 120 |

| 40-60 | 70 |

Derating tip

In-situ gravel-pack permeability is often lower due to fines and contaminants. A 50 percent reduction is commonly recommended.

PERFORATION DIAMETER (in): Average hole diameter through casing, cement, and formation. Controlled by charge, gun, and formation strength. API RP-43 data for the selected charge provides an upper bound. Typical range is 1/2 in to 7/8 in.

FLOW LENGTH (in): Linear distance fluids travel through the gravel pack. Usually the hole radius minus the screen radius. If you believe flow is linear through the perforation tunnel too, include it, though the first method is recommended.

Recommended expression: L = r_w - 0.5 * d_s

where L is flow length, r_w is wellbore radius, and d_s is the screen outside diameter. Equivalent: L ≈ R_h - R_s.

PERFORATED INTERVAL (ft): Length of the perforated section for the zone of interest, taken from the completion report. Multiple zones may be open, each with its own interval.

SHOT DENSITY (spf): Designed perforations per foot. The effective count is reduced in the program by the Perforation Efficiency.

PERFORATION EFFICIENCY: Probability that a perforation provides a full flow path. It combines the probability of a good fire and complete traversal of casing, cement, and damage zones. Typical values are 0.5 to 0.9.